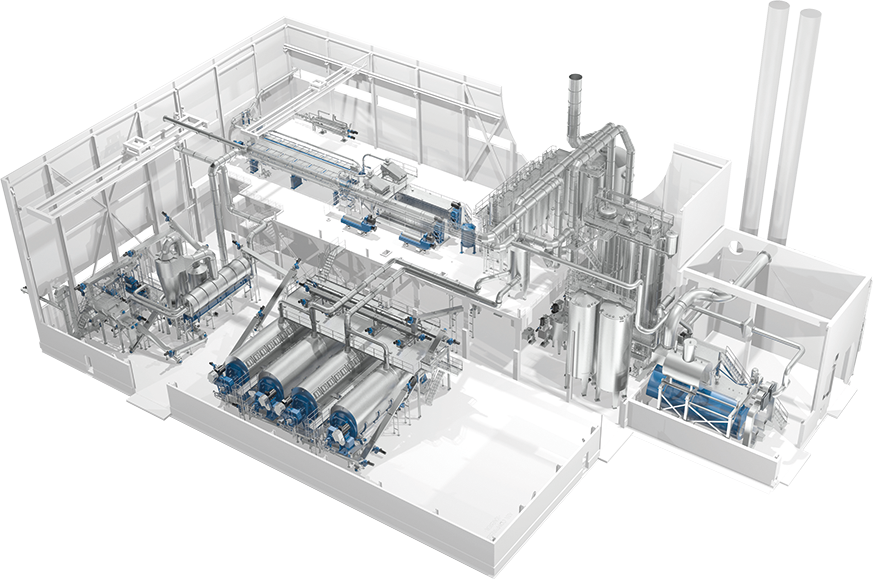

Fish meal and oil processing

The most reliable, effective solutions for processing fish meal and oil – customized and configured to your exact operating requirements.

GLOBAL MARKET LEADER

We’re the world’s leading supplier of technology that fisheries operations use to process catches and by-products into fish meal and oil – improving product quality, reducing energy consumption and expanding commercial opportunities.

We design, build and deliver systems renowned for their reliability, energy efficiency, safety and compliance with local as well as international environmental standards.

FULL RANGE - YOUR CHOICE

Haarslev provides a comprehensive product range that extends from small units and individual items of equipment up to the largest fish oil and meal plants in the world, and is backed by the in-depth, specialist know-how you need to make sure these systems work at peak efficiency – and keep on doing so for a long time.

Whether you are looking for a fish meal and oil processing plant on land or on-board a vessel, Haarslev has the solution for you.

Below you can learn more about your options

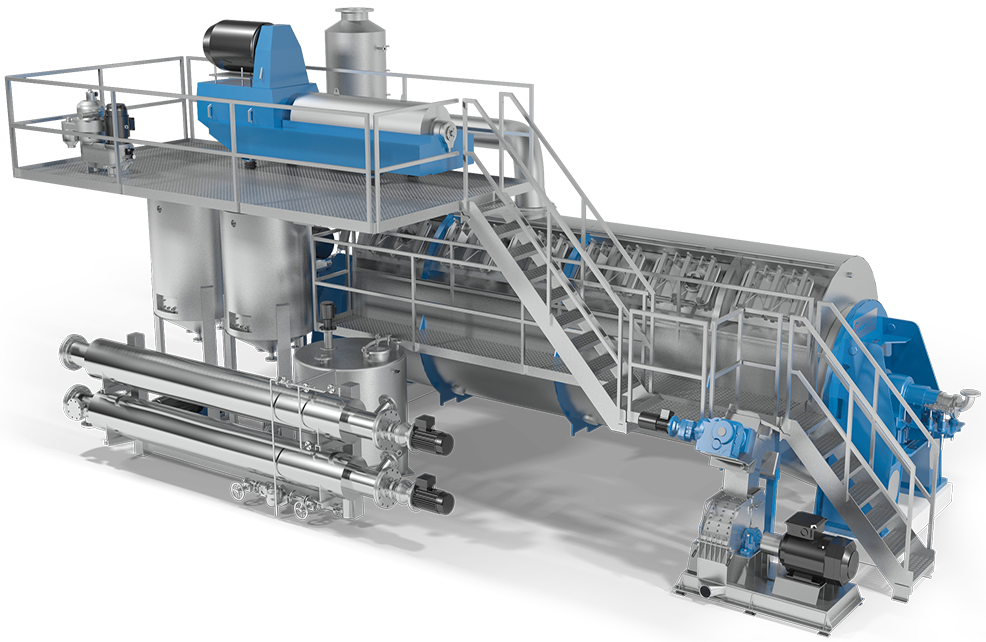

STANDARD PROCESSING LINE

These compact, sturdy systems are extremely well-known throughout the fishing industry – renowned for their reliability. They all feature rugged specifications and technical features that’re specially designed for a long service life.

80% faster cooking results in gentler product handling and better meal and oil quality. These systems cost less to run, which means they give you greater processing capacity per unit of expenditure.

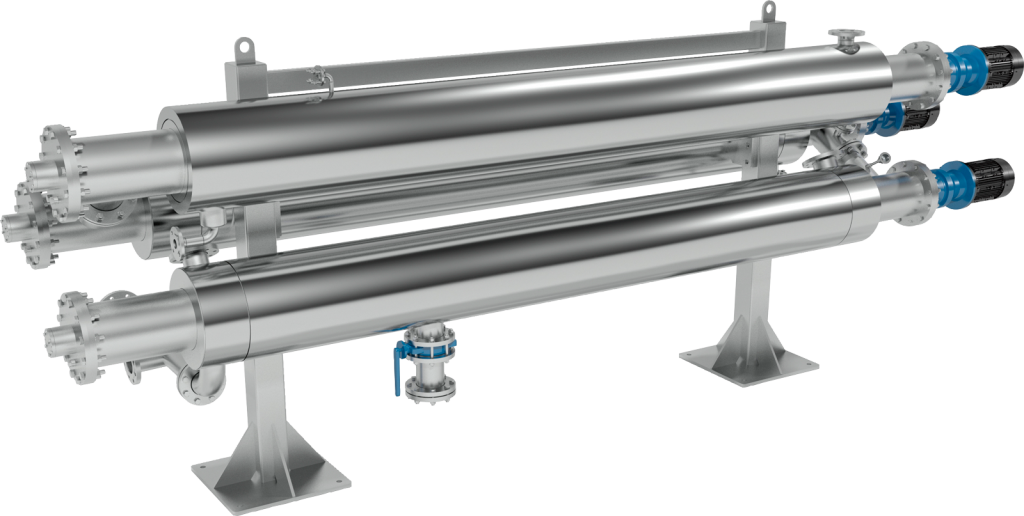

HIGH-GRADE PROCESSING LINES

These specialized systems are specially designed to provide high-grade fish meal and oil that can comply with higher specifications (such as 3% higher digestibility), and thus sell for higher prices. Because of the specifications, these systems are more expensive, but they enable you to generate more revenue from any given catch as well as to occupy a different position in the market for fish meal and oil.

Taking care

of tomorrow

Haarslev Global Services makes sure your business keeps on going

Downtime is the worst for all companies. You just have to avoid it at all costs. Our systems have been designed to ensure maximum uptime.

Haarslev Global Services department helps keep your plant running reliably, efficiently and profitably every day of the year.

Highly trained experts are available to give you the best advice when it comes to mastering your processes and by implementing the right procedures for maintenance and spare parts stock, you will be able to:

- guarantee your throughput

- obtain more yield per product

- achieve a reduced Total Cost of Ownership (TCO)