Food processing

Solutions

Fresh raw material which is not going directly to the consumers market creates food grade leftovers that can be downgraded to feed products. This means lower yield and loss in production. Haarslev helps you turn the leftovers into a valuable source of income, by turning it into high-quality protein powder products for the food or meat market or into a high-quality ingredient for the pet food industry.

solutions

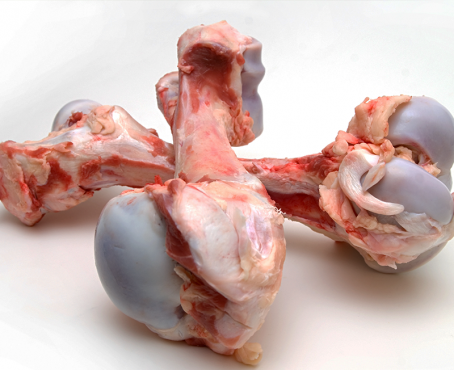

Suitable raw materials are: fresh poultry meat and bone leftovers, mechanically deboned products, animal bones, connective and fat trimmings and seafood by-products.

Poultry

Processing

From the poultry application fresh meat cuts, trimming or carcass can be collected and chilled before they are processed into flavour soup extract or broth product. The final product can be concentrated liquid and can be sold in chilled form or dried into a powder with outstanding taste, nutrition and 100% solubility.

Available process solutions-

Digestion BONE EXTRACT Processing Line

A continuous digestion process engineered system for meat and bone material to customer specification from low to medium capacity.

-

BONE SOUP (BROTH ) Processing Line

A continuous pressure cooking process engineered system for meat and bone material to customer specification from low to medium capacity.

BONE

PROCESSING

From the deboning rooms in a slaughtering or meat producer’s plant, fresh meat cuts, trimming or bone leftovers are collected and turned into a food ingredient or a meat substitute final product. The final liquid product is concentrated and can be sold in chilled form or dried into a powder with good functionalities and nutrition value.

AVAILABLE PROCESS SOLUTIONS-

Digestion BONE EXTRACT Processing Line

A continuous digestion process engineered system for meat and bone material to customer specification from low to medium capacity.

-

BONE SOUP Cooking Processing Line

A continuous pressure cooking process engineered system for meat and bone material to customer specification from low to medium capacity.

FAT AND PROTEIN

PROCESSING

From the deboning rooms in a slaughtering or meat producer’s plant, fresh trimming cuts and fat leftovers are collected and turn into a food grade edible lard or tallow and an edible protein meat as substitute final product with enhanced functionalities.

AVAILABLE PROCESS SOLUTIONS-

Fat and Melting Processing Line

A continuous engineered system to process fatty cut off and trimming material into food grade fat and functional edible protein to customer specification from low to high capacity.

FISH OIL

PROCESSING

From the seafood application fresh head frame and fish skin and partly organs can be pumped to a process line to make high grade fish oil for food or nutraceutical purpose. Extreme fresh raw material like liver can be processed in a few minutes, which offers a high-grade fish oil product like COD liver or other fish enriched with EPA and DHE content.

AVAILABLE PROCESS SOLUTIONS-

Ultra Short Processing Line

A continuous processing modulated to make high-grade fish oil.

Taking care

of tomorrow

Haarslev Global Services makes sure your business keeps on going

Downtime is the worst for all companies. You just have to avoid it at all costs. Our systems have been designed to ensure maximum uptime.

Haarslev Global Services department helps keep your plant running reliably, efficiently and profitably every day of the year.

Highly trained experts are available to give you the best advice when it comes to mastering your processes and by implementing the right procedures for maintenance and spare parts stock, you will be able to:

- guarantee your throughput

- obtain more yield per product

- achieve a reduced Total Cost of Ownership (TCO)