Introduction

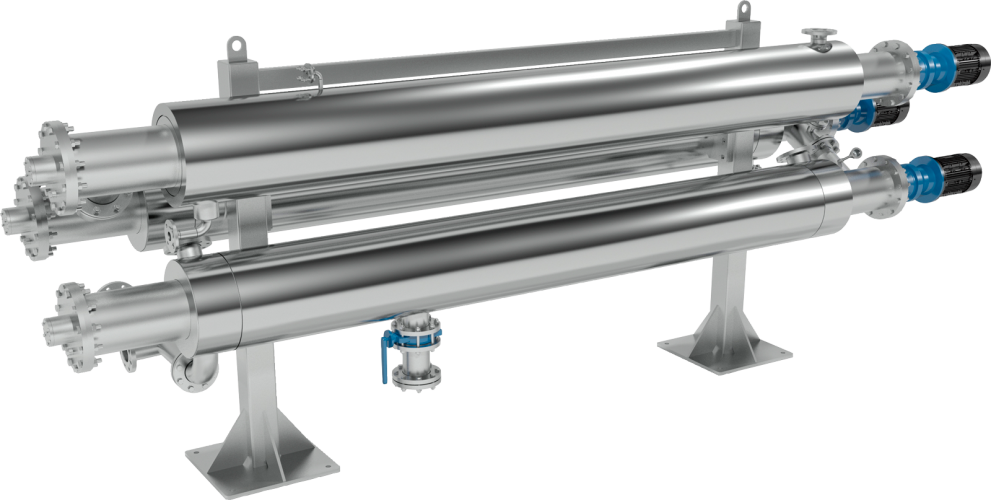

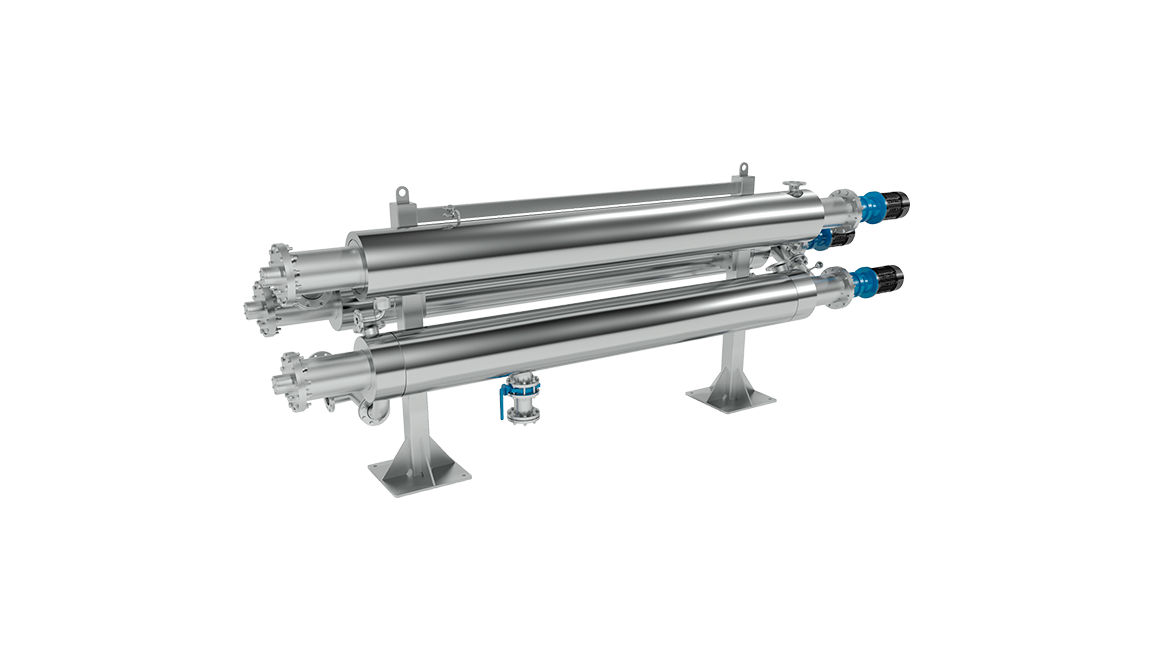

The Haarslev Compact Coagulator is a horizontal, self-cleaning heat exchanger that uses indirect steam heating to cook relatively liquid fish and animal-based raw materials so they coagulate in accordance with your requirements for effective downstream separation.

This space-saving cooker is a continuous-feed unit, normally with multiple cooking tubes connected in series. Your relatively wet raw material – often a slurry or in some other viscous state – is pumped through these narrow tubes. Steam flows through the casing in the opposite direction and very quickly heats the slurry to the required temperature. This means it can exit the cooker much quicker than with traditional screw-type cooker units, and wet inputs are exposed to high temperatures for only a very short time – significantly boosting the quality of your output.

Exploiting the thermal efficiency available from scraped-surface heat exchanger technology, these cookers are Ideal for smaller throughputs and for specialty processes aimed at niche products, often featuring ultra-high-quality proteins.