Introduction

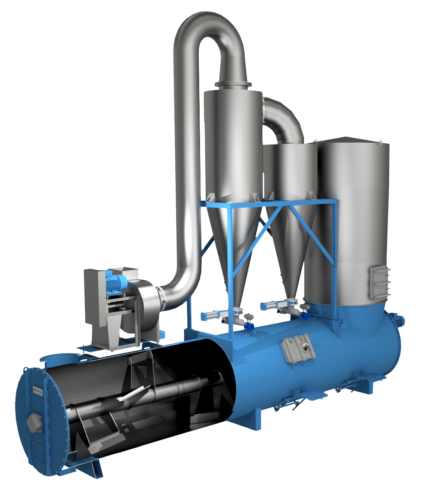

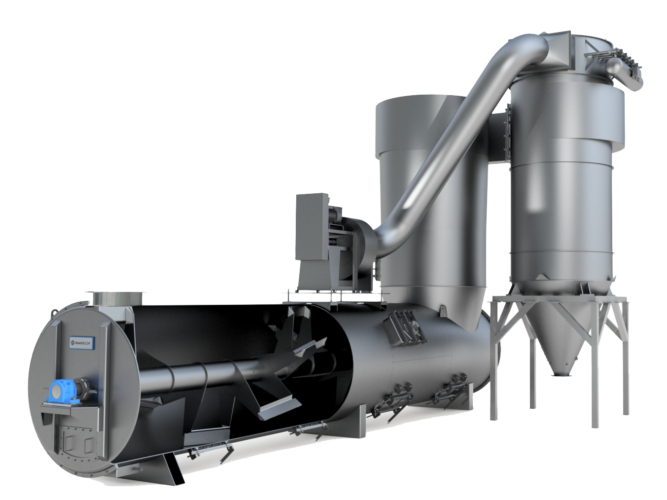

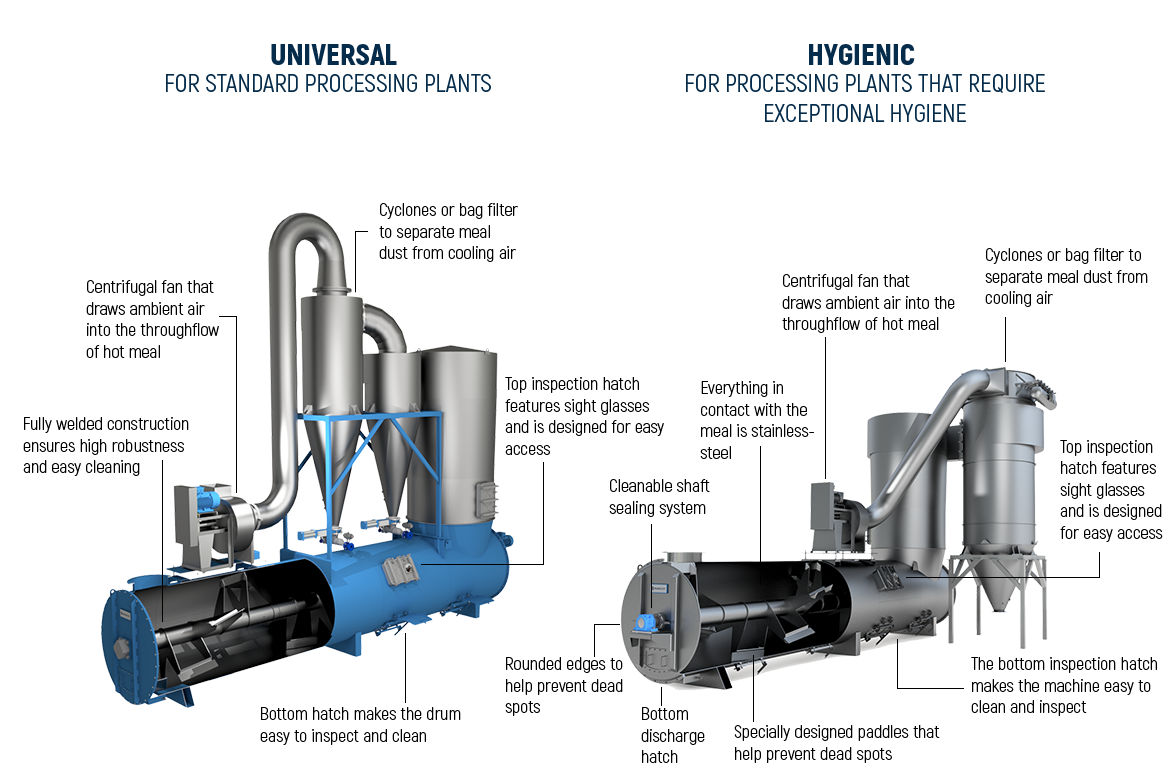

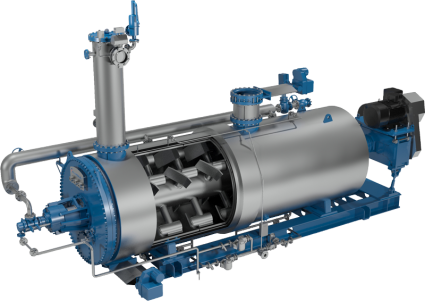

This robust, hard-wearing cooler enables you to use ambient air to cool a broad range of meal products (usually derived from poultry, fish or meat) after they have passed through a drying or cooking process. Cooling helps make the processed cake more brittle, so it’s easier to mill.

More importantly, such cooling also enables you to make sure storage temperatures are kept below 50°C, to help prevent any risk of the meal self-igniting. The cooler itself is fundamentally a long drum equipped with an agitator.

The agitator moves the hot (usually 90–110°C) meal through the cooler, while a counterflow of cooling air is drawn through by a centrifugal fan. The cooling air you use can either be ambient air or air from other suitable processes elsewhere in your plant – usually at approx. 20–30°C above ambient temperatures.

Rugged construction, few components and wearing parts makes this a reliable, inexpensive way to cool a wide range of meal products.