Introduction

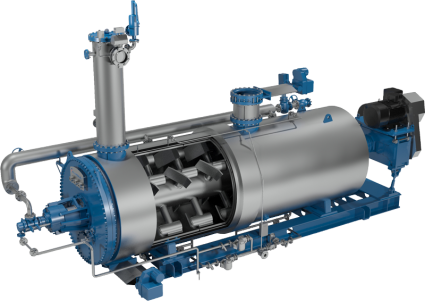

A Haarslev Disc Cooker is the ideal solution for removing as much water as possible, as gently as possible, from animal or poultry by-products with a relatively high fat content. Designed to use steam pressures of up to 10 bar, these cookers are the preferred choice for coarser inputs.

They are good at dealing with animal by-products with fluctuating dry/wet specifications, prior to downstream fat separation and tallow polishing. Additional tallow can be added, if necessary for greater cooking efficiency.

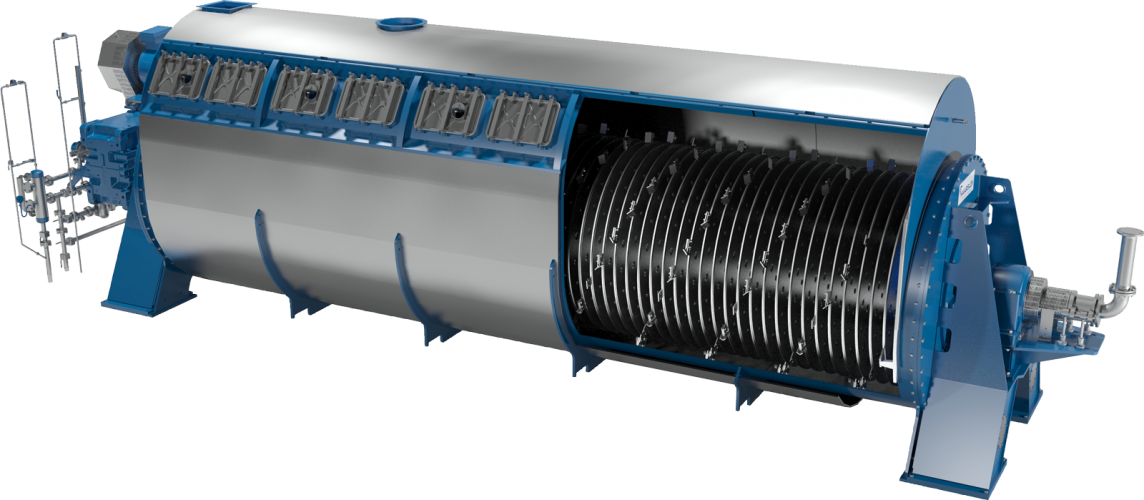

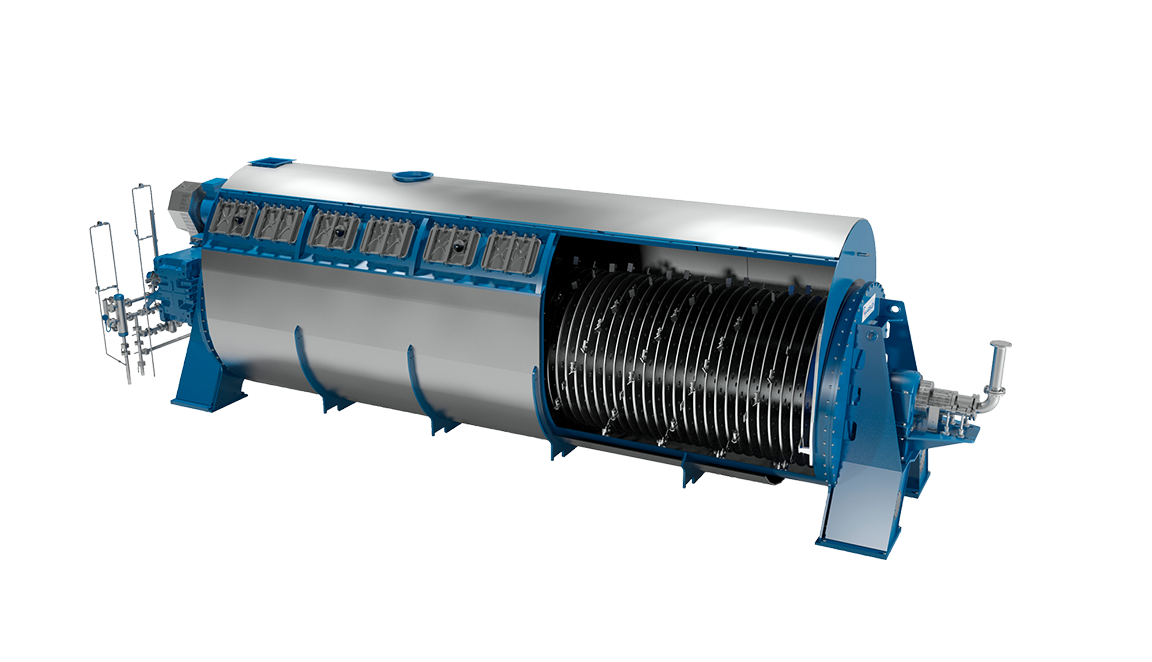

These sturdy, reliable units are built around a rotor consisting of a central shaft fitted with multiple steam-heated discs. These apply indirect heat over a very large area, in a compact design that quickly and effectively removes the evaporated water vapor. This means as much heat as possible gets transferred to the material in the cooker.

The dried material is discharged at the bottom, using a screw conveyor fitted with variable-speed drive. This can be adjusted independently of the cooker itself, providing maximum flexibility.