Introduction

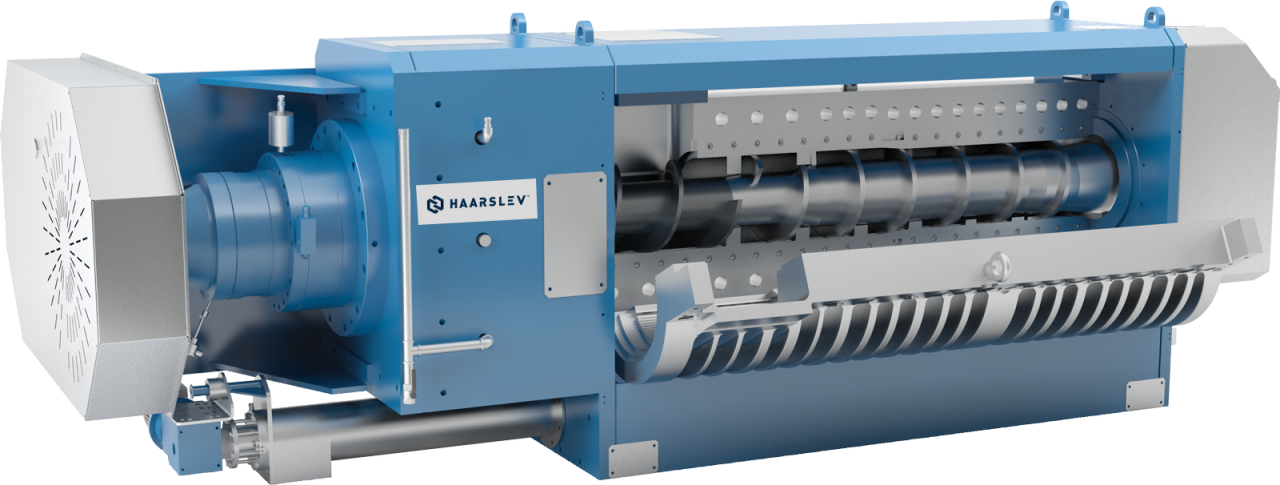

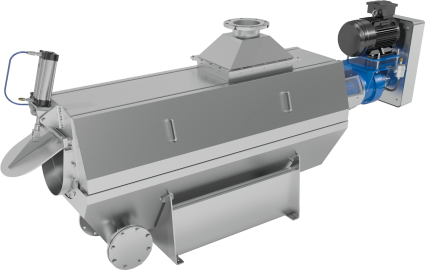

The Haarslev Fat Screw Press provides highly effective mechanical extraction of the fat content from cooked and dried animal and poultry by-products, in a continuous flow. This enables you to achieve a hard cake with a low fat content.

As the greaves pass along the single conical screw, the fat is pressed out into the surrounding enclosure, and the greaves are discharged as press cake. The fat (along with any solids – often known as fines) runs into a collector trough, where a screw moves it to the outlet.

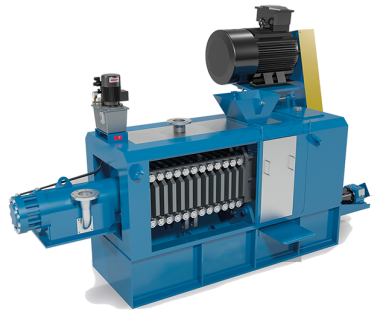

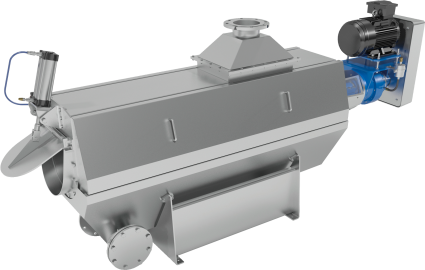

These solidly built units are simple but effective, ensuring maximum reliability and low service and maintenance costs. Two different models are currently available:

- Shorter ST model with hydraulically adjustable choke in the outlet

- Longer, high-capacity HM model with fewer moving parts and no choke in the outlet