Introduction

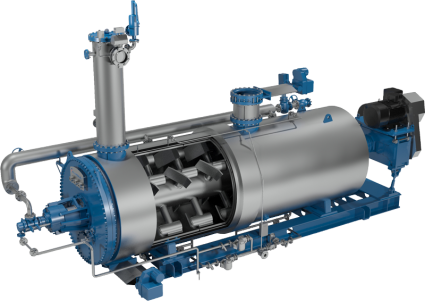

Haarslev metal detectors effectively remove a wide range of metal items from raw or cooked material, using a detector head with adjustable sensitivity. This can be used to trigger a separation device, or to stop the flow of material.

Any pieces of metal and metal residues – whether ferrous metals or stainless steel – are efficiently separated mechanically, with only a minimum of material being ejected with them, thus keeping waste to a minimum. Manual removal may be necessary in some processing setups.

Haarslev metal detectors can be used in a wide variety of places and processing streams. You pick the technology and the configuration best suited to your particular inputs, flows and processing configurations.

Haarslev experts are on call to help you quickly and painlessly integrate a metal detector setup into your particular processing requirements and equipment configurations.

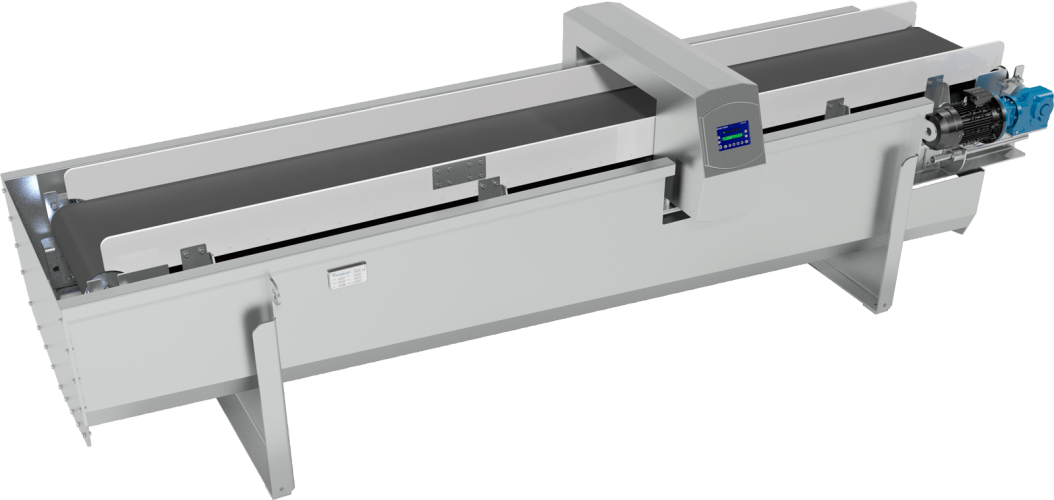

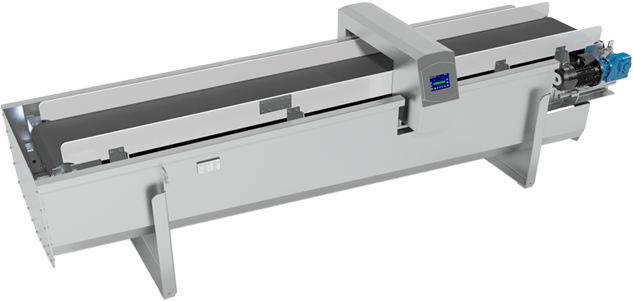

Belt conveyor with metal detector

The belt conveyor is configured to order and available in stainless or mild steel. A deflector can be mounted at the end of the conveyor, or metal can be removed manually.

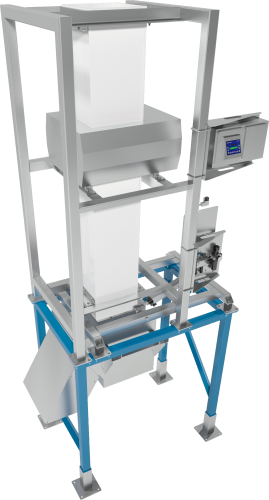

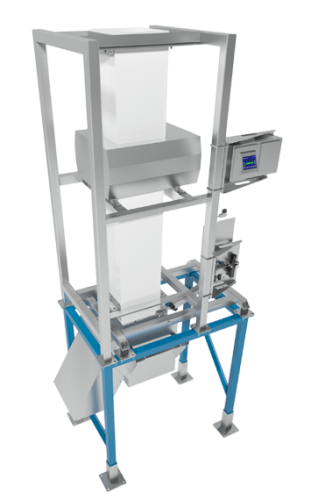

Vertical Metal detector

The vertical metal detector system is configured to order and built on a single frame and delivered as a single unit. It is available in stainless or mild steel.

This type of Haarslev vertical metal detector is fully automatic, and detects any metal present when the material falls through a non-ferrous pipe. A pneumatically operated diverter then removes any metal items present.

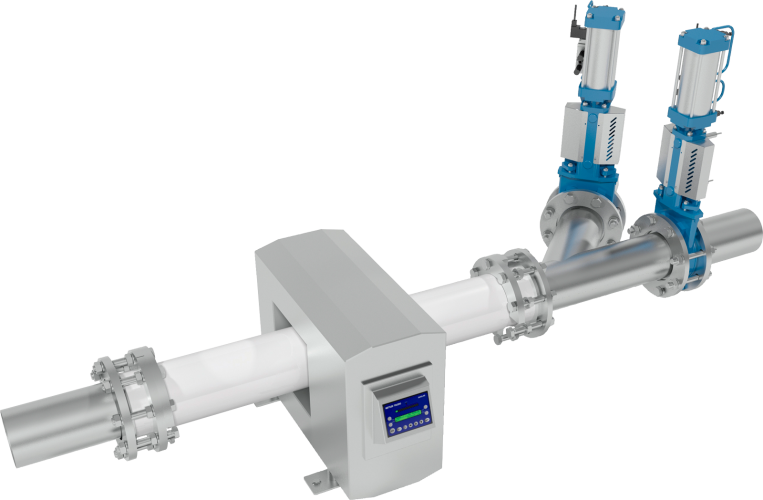

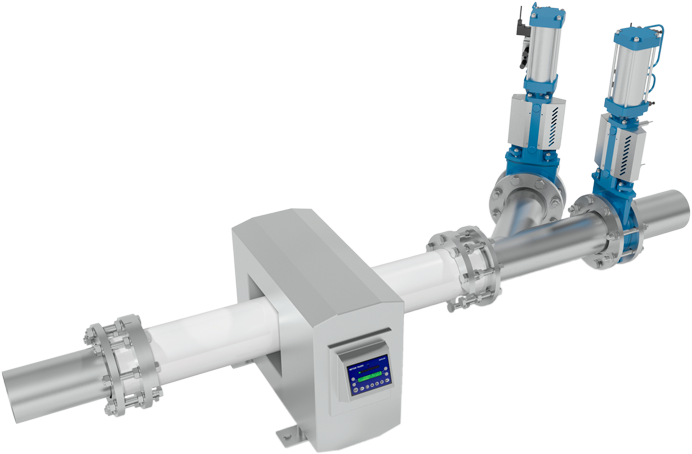

Pipe Metal detector

The pipe metal detector is a clean, closed system that takes up a minimum of space.

This kind of system requires a constant flow of material in the piping system.