Introduction

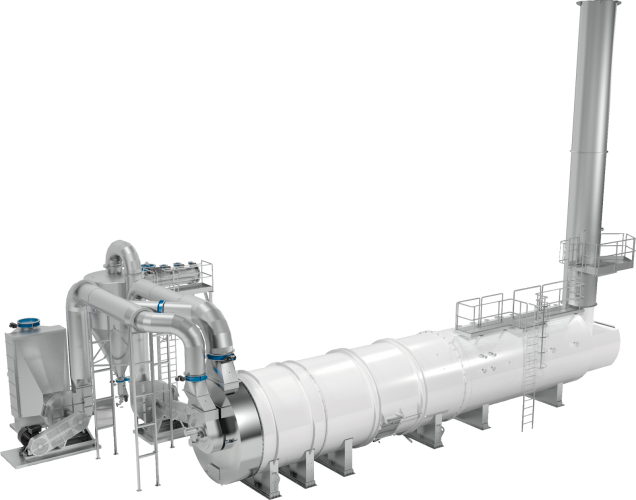

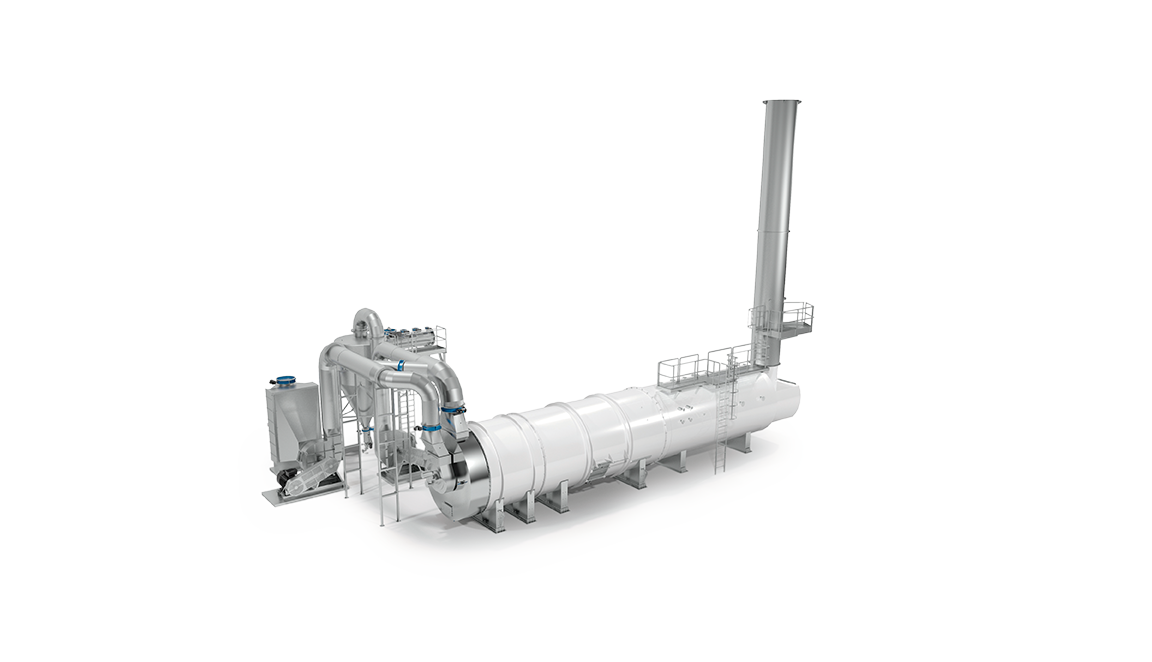

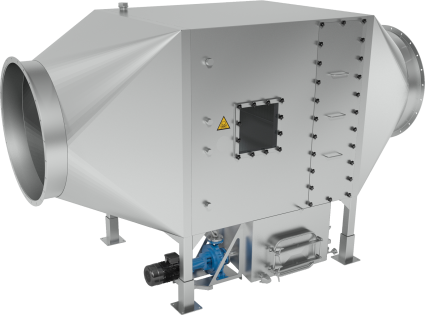

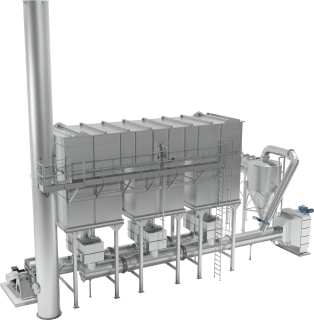

You can quickly and effectively get rid of virtually all unpleasant odors in the gases and vapors from your rendering plant by exposing them to very high temperatures in combination with the presence of oxygen. This triggers an oxidation reaction that transforms the problematic complex organic solvents into simple, easy-to-dispose-of mixture of mainly CO2 and H2O.

This provides you with an energy-efficient way to ensure compliance with increasingly stringent environmental requirements. Another big upside is that energy from the oxidized hot gases is recovered using a steam boiler that generates large quantities of valuable steam for use elsewhere in your rendering plant or in other processing equipment.