Introduction

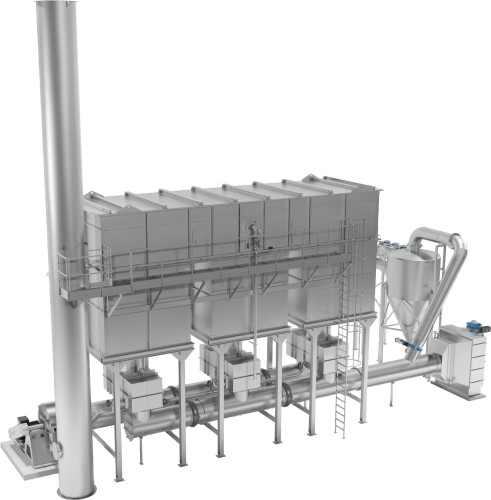

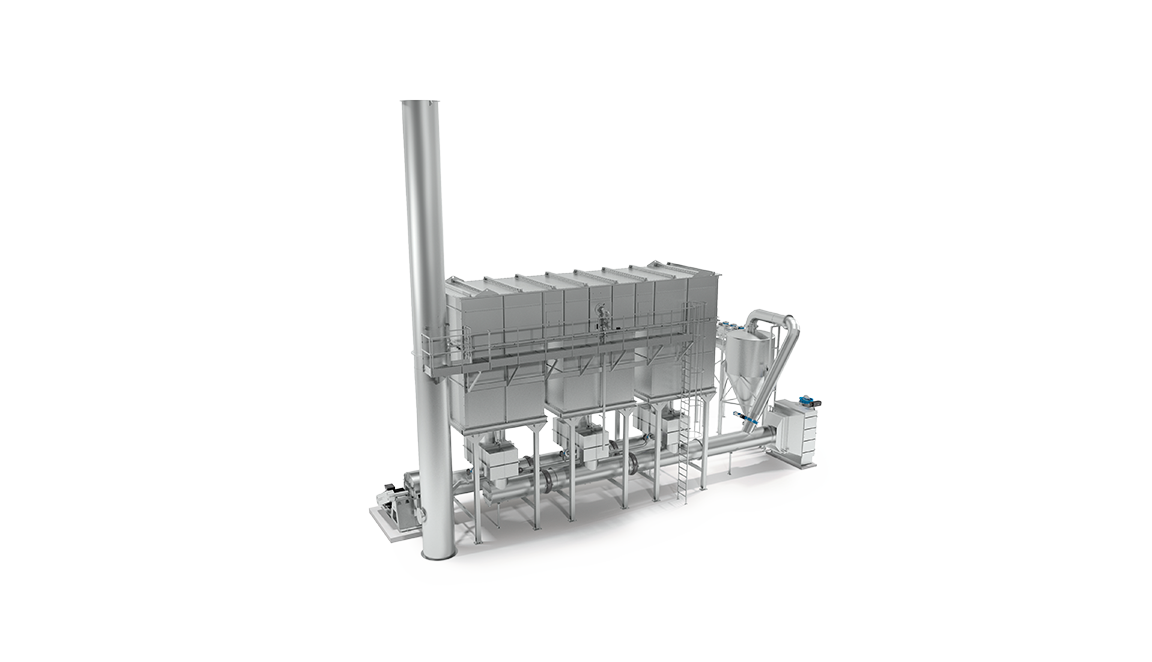

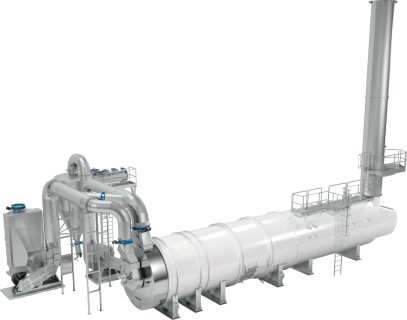

According to the EU Environmental Protection Agency, this is the best-available technology (BAT) for combating unpleasant odors in gaseous air flows from cookers and dryers used in rendering processes. A Haarslev Regenerative Thermal Oxidizer guarantees minimum 98% odor reduction at the same time as ensuring the highest possible thermal efficiency.

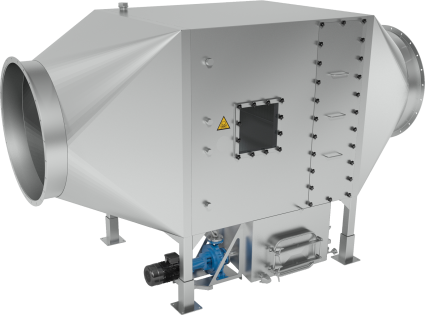

This regenerative thermal oxidizer system is built around a high temperature oxidation process that inputs gaseous effluents with a complex and variable composition of odor causing compounds to be broken down into simple, easy-to-manage mixture of gases mainly composed of CO2 and H2O, while using as little energy as possible.

The exceptional energy-efficiency of this system stems from the fact that a substantial proportion of the thermal energy needed for the oxidation process is continually transferred to – or recovered from – the special ceramic material inside the three large vertical rectangular sections.

Haarslev is the only manufacturer that builds both rendering and thermal oxidation systems, ensuring customers the best possible integration and streamlining of these two key technologies and systems.