Introduction

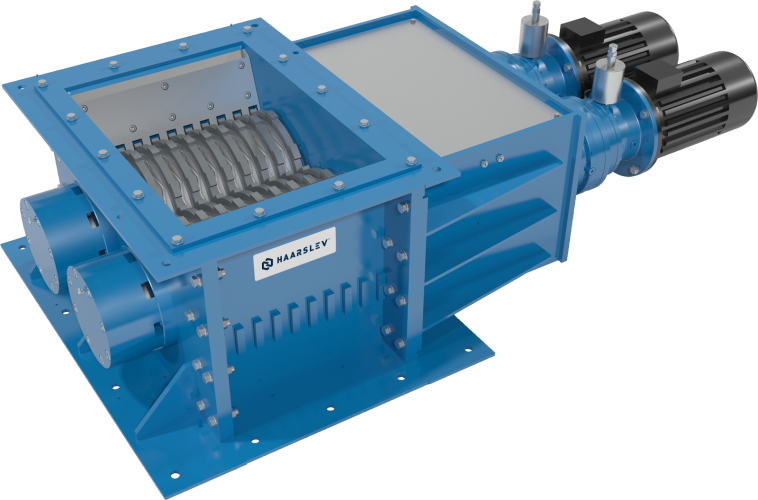

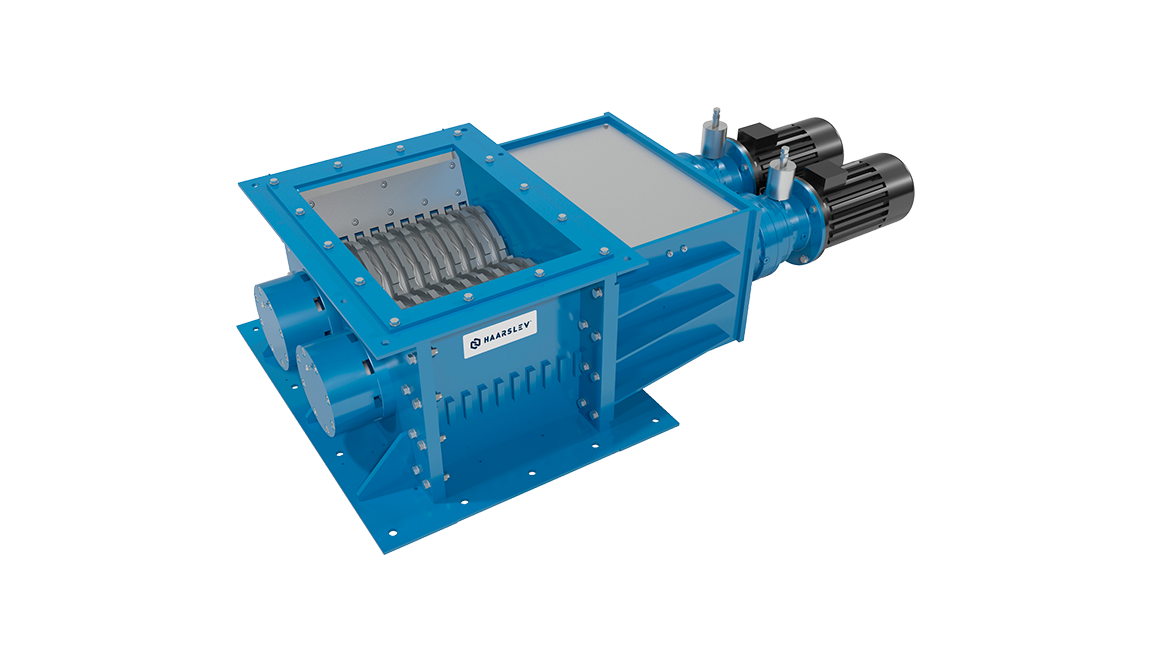

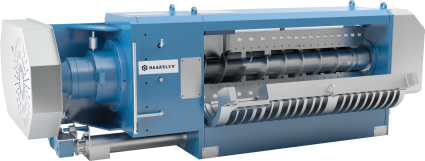

The Haarslev Roller Crusher makes sure particles of cooked animal by-products have a consistent size before they are sent for fat separation in dry rendering processes. A roller crusher is particularly effective in breaking down the biggest particles of bone, because bone is relatively brittle and therefore easier to crush. Any particles in the greaves exiting the roller crusher unit have been reduced to a maximum size of about 25 mm.

Another big practical advantage is that any larger pieces of metal that might be present are caught in this roller crusher, instead of damaging the fat screw presses elsewhere in your processes.