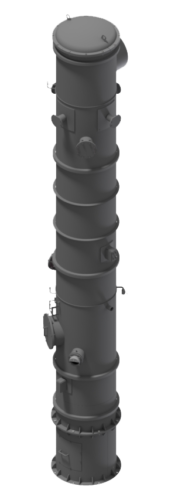

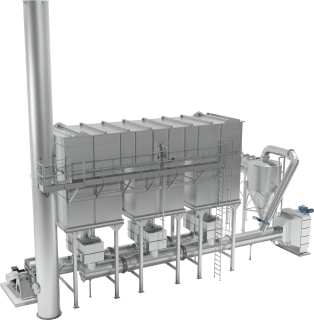

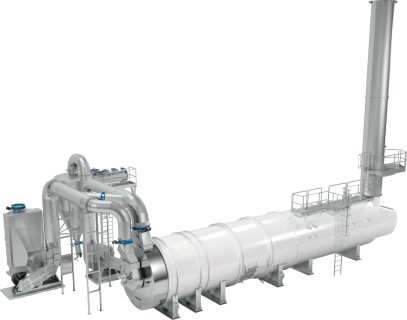

Design

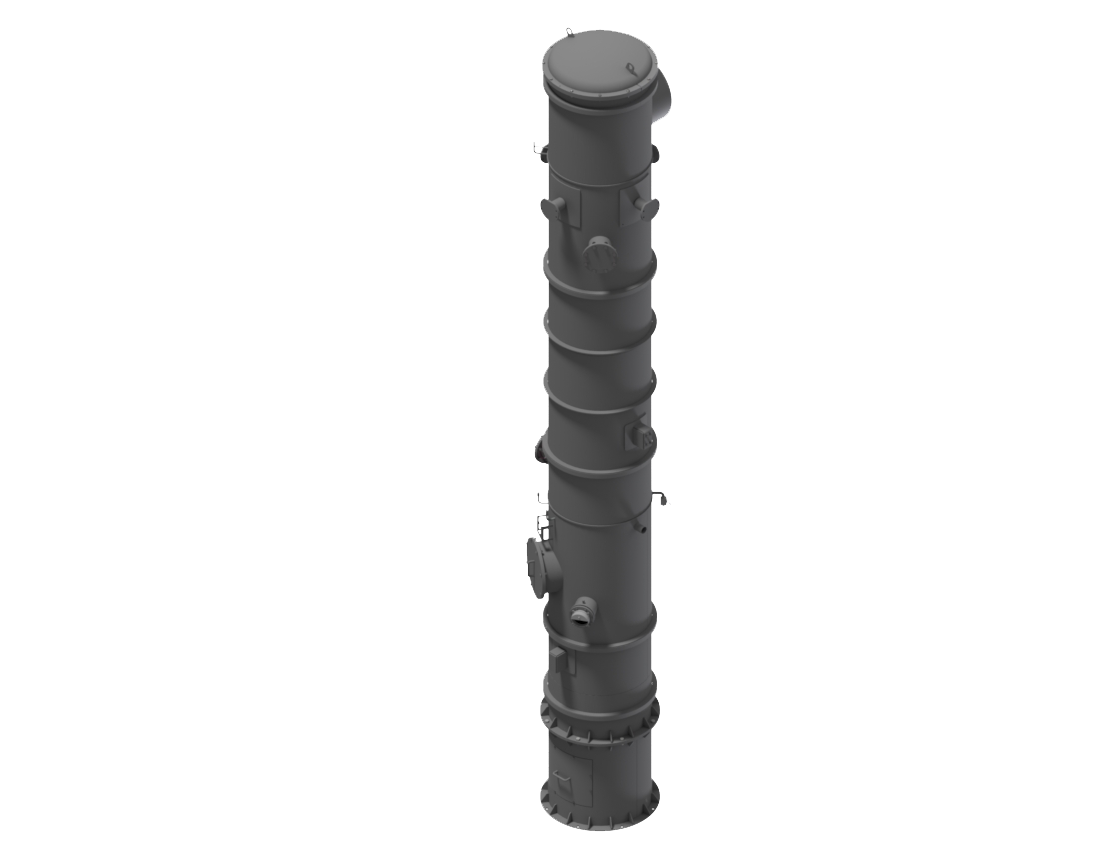

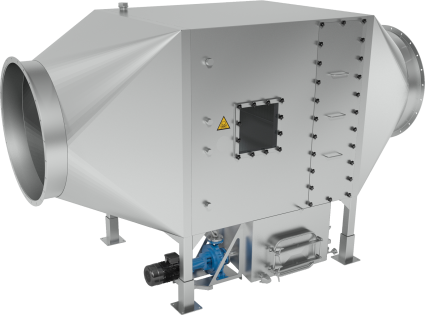

The many types of cookers and dryers used in meat rendering and fish meal plants produce large quantities of hot gases and vapors that can be hard to deal with or dispose of responsibly. Haarslev shell & tube heat exchangers quickly and effectively bring these vapors into an easy-to-handle liquid form, using only a minimum of energy – for pumps to circulate the cooling water.

This setup draws the vapor out of such cookers and dryers, because energy always flows to the coldest point. This makes it easy to separate the non-condensable gases (VOCs), leaving just condensed water as effluent.

You can also use the thermal transfer capabilities of these units to recover waste heat and/or valuable thermal energy to heat wash-down water or to reduce operating costs elsewhere in your plant.

This shell-and-tube condenser design is ideal for installations with sufficient space for large equipment.