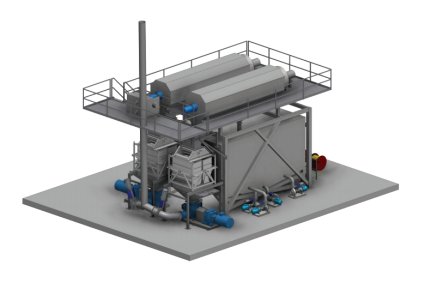

Haarslev evaporators are an integral part of an effective dry rendering setup, playing a big role in improving the overall efficiency of the downstream cooking process by evaporating the water content of stick water.

The most widely used Haarslev evaporators use the falling film principle to concentrate these liquids, drawing thermal energy from the dryer in order bring the liquid up to temperatures at which the water content evaporates. This means you can achieve higher concentrations at lower cost, and also recover the dissolved higher-protein solids to boost yields in your meal production setup.

In Haarslev evaporation systems, you can install these evaporators in multiple effects, reducing operating costs by using the vapor produced in one effect to provide heating in the subsequent evaporator. This means the temperature difference per effect falls (and thermal efficiency increases) as the number of stages increases – a three-effect evaporator uses about one-third as much steam as a single-effect unit.

Haarslev evaporators are available in four distinct configurations, based on different technologies. These can be combined to meet your particular processing requirements. You can (for example) use a steam-heated evaporator as a finisher to boost capacity from an evaporator setup fuelled by waste heat.

Haarslev Evaporators

Waste-heat falling-film evaporator

uses waste heat from a dryer as a heat source, often re-using steam in multiple stages for maximum thermal efficiency

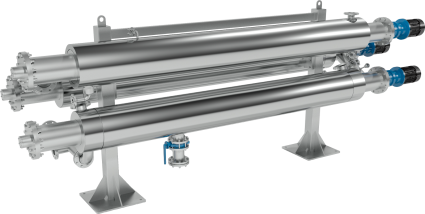

Steam-heated falling-film evaporator

uses live steam as the heat source, enabling you to achieve higher concentrations. Can also be installed as a finisher after multiple evaporator effects, to boost concentration capacity. Haarslev can also provide two other technology setups to meet specific requirements.

Forced-circulation flash evaporator

in which the liquid to be concentrated is pumped from the bottom to entirely fill the evaporator chamber, before it flashes off into a separate chamber.

Heat pump evaporator or Mechanical vapor recompression evaporator

ideal if no waste heat is available or the vapor flow is unsuitable – or if you can source electricity at very low cost.

Applicable for

- Different pressing operations used in dry rendering processes result in solid and liquid components. The liquid usually contains both dissolved and suspended solids, and the latter are removed mechanically with a three-phase decanter centrifuge, leaving behind stick water that usually contains 4–6% solids. The dissolved solids contain higher levels of protein, so recovering these enables you to increase the protein content in the end-product meal.

- An effective evaporator can help you concentrate these up to about 30% solids, so that the material can be circulated back to the dryer for effective recovery.