Introduction

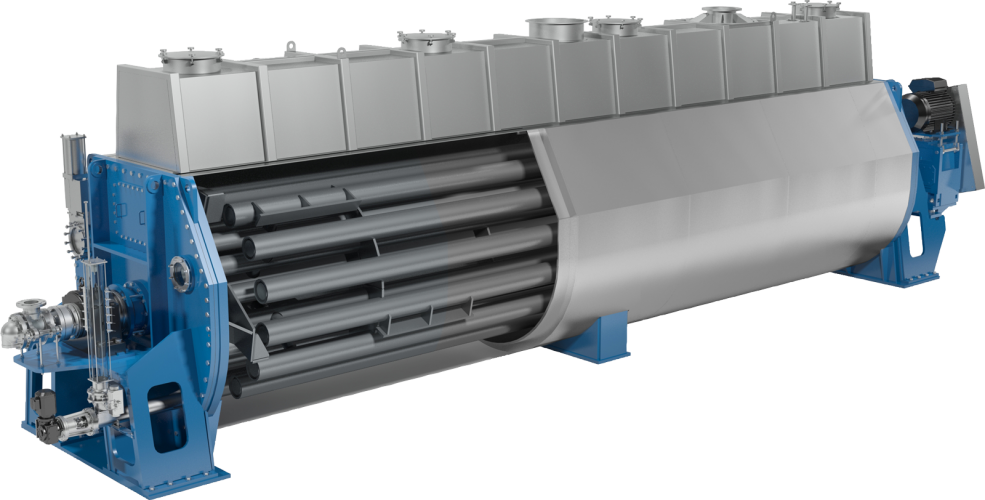

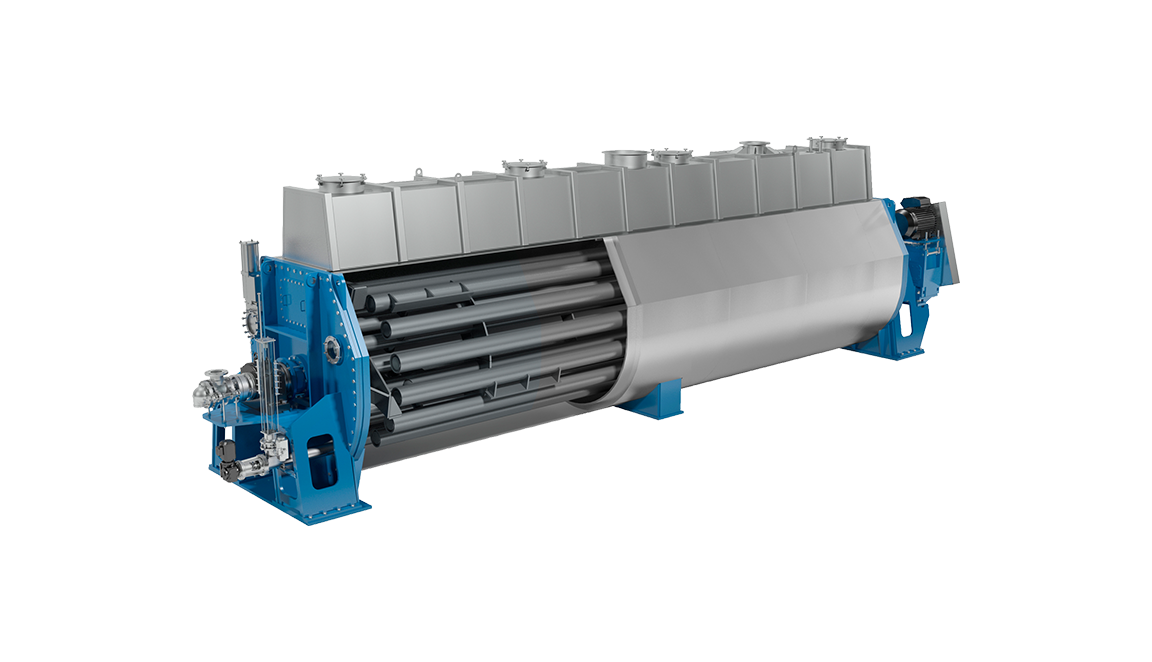

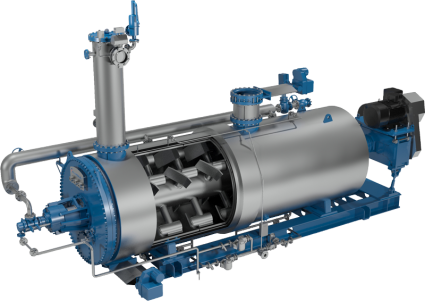

If cooking animal by-products such as meat, bone and fat is part of your processing setup, a steam-heated Haarslev Continuous Cooker can help you improve both operating efficiency and profit margins from such inputs.

Designed to use steam pressures of up to 10 bar, this straightforward, easy-to-operate cooker is ideal for removing water in continuous processing setups, ensuring fats and solids outputs that are both consistent and homogenous.

They provide evaporation capacities from 1,300 kg/hour up to 14,000 kg/hour. And you can easily adjust cooking temperatures to match the specifics of your particular processing requirements and the raw material specifications you have available.

Your inputs enter at the bottom of the cooker and discharge at the top, forcing the fat and bone through the cooker. Tallow is pumped in to keep the material flowing through the cooker, and is continually recirculated for maximum thermal efficiency. A sophisticated automatic level control system regulates the input flows to prevent any cooking inefficiencies associated with under- or overfilling.