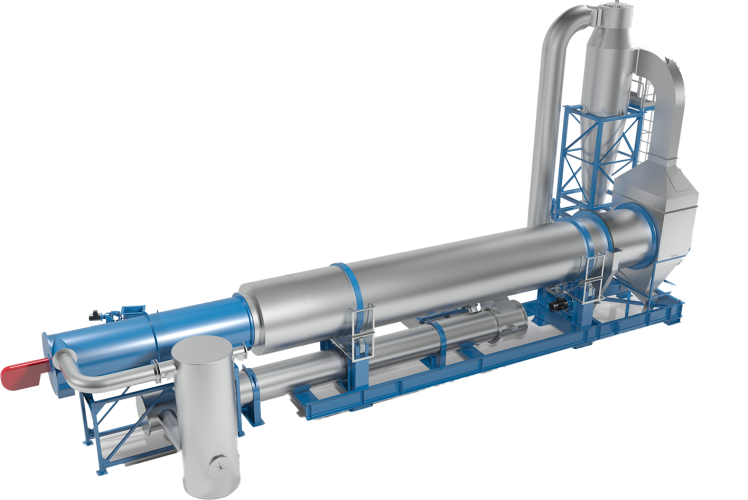

The Haarslev Rotary Drum Dryer for Sludge is a directly fired, single pass, rotary drum drying system with advanced sizing screening and granulation techniques producing a dust free granule suitable for reuse in agriculture and as fuel.

The system features process gas recirculation with a unique indirect condensing heat exchanger to minimise effluent retreatment in the WWTP and also minimise the off-gas volume sent to odour control.

The drying system is offered as a complete system including the latest in safety enhancements in full compliance with NFPS/ATEX regulations and includes a sophisticated process control system for both safety compliance and the possibility of unattended operations at night.

The rotary drum dryer is a direct-fired hot air cascading type of dryer, which dries sludge to between 90 to 95 % dry solids. The material is gently dried as it cascades through the hot air flow.

The hot air stream is provided by a direct-fired gas burner normally operating with natural- and bio-gas. This generates high inlet temperatures for rapid surface heating and immediate pathogen destruction. The process maintains a safe low oxygen atmosphere inside the dryer loop. Recirculation of hot gas reduces thermal energy consumption.

The Haarslev Rotary Drum Dryer has a minimum of moving parts, which means reduced wear, less maintenance and increased operating life.

A range of fuels including natural gas, synthesis gas, methane, LPG, oil, coal or bio-gas can be used. It can also be supplied with indirect heating systems utilising waste heat from e.g. turbine exhaust gases.