Introduction

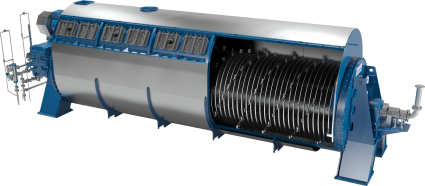

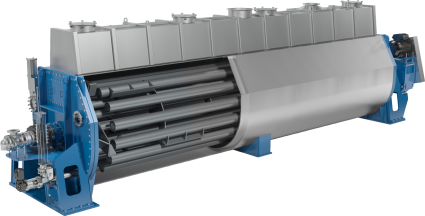

In many processing setups, it’s quite normal to send the pressurized condensate from disc dryers and continuous and/or batch cookers back to the feed-water tank of a boiler system.

If nothing is done, the flow simply de-pressurizes (flashing), resulting in a significant loss of temperature and pressure, as well as venting water to the atmosphere.

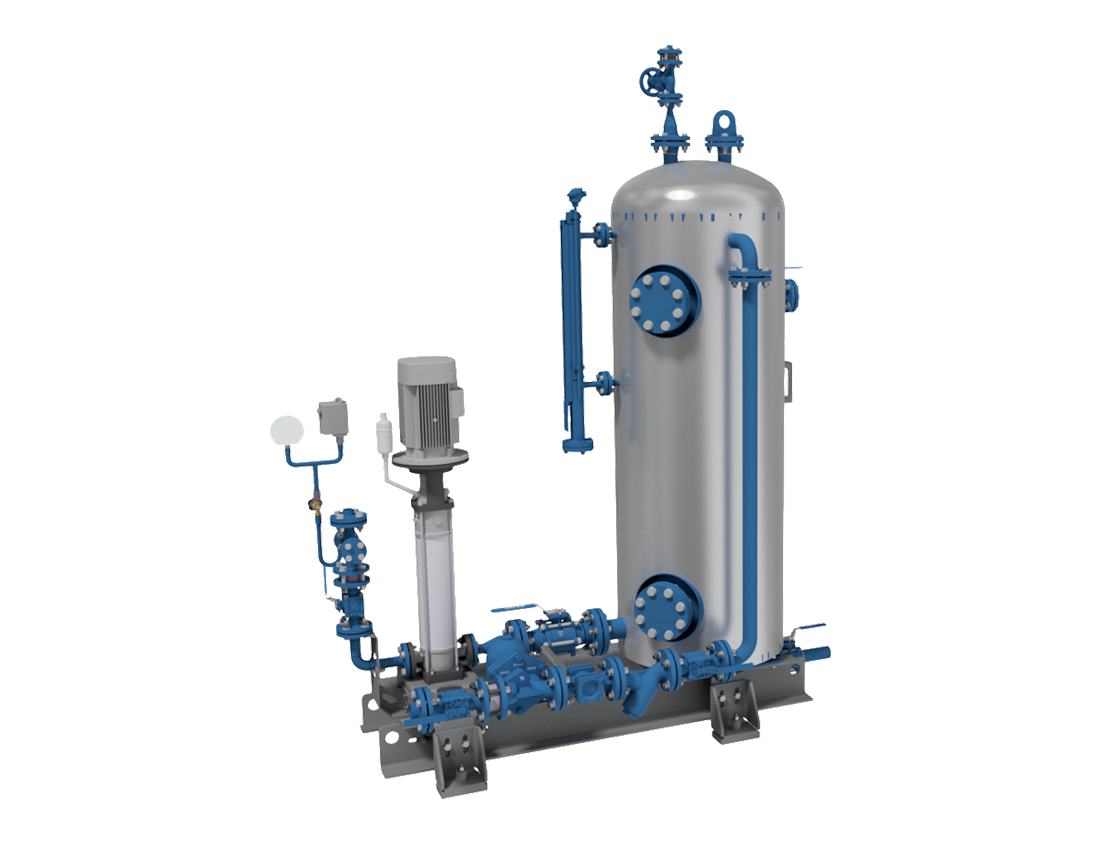

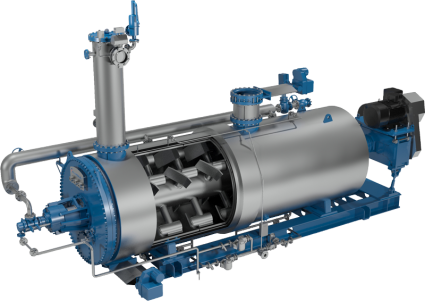

Instead, the Haarslev Steam Condensate Return System sends such steam condensate directly to the boiler – still under pressure – by means of a special feed tank.

This nearly eliminates the energy losses, and means your boiler setup doesn’t use as much fuel and water. You also get better boiler performance, because the water temperature inside the boiler no longer fluctuates as much. Maintaining pressure means you can save as much as 15% on your steam production costs.

The system is easy to install in any existing steam/condensate/steam boiler setup, and provides significant reductions in your operating costs by eliminating steam pressure and water losses between the connected cooking or drying equipment and the boiler.